DP-FsE series

DP-FE/D series

Corrosion-resistant Non-metallic Specification! Safe Design with Intrinsically Explosion-proof Specification.

A non-metallic model diaphragm pump that uses resin as the material even for the main parts, and employs a fiber-optic stroke sensor control model of the DP-Fs series.

Even if the one-piece diaphragm is damaged, metal ion contamination is prevented, and the pump can be operated with peace of mind in a corrosive environment, so it is suitable for CMP slurry transfer.

■ Main Applications

Transfer of Flammable Liquids in Explosion-proof Areas/Transfer of Chemicals, Pure Water, and Waste Liquids

Features

■ Seal Specification

| Hard Seal Supports expansion and contraction of the resin due to the heat cycle, and is resistant to temperature changes. |

|

■ Non-Metallic Specification

| One-piece Diaphragm Center disk less diaphragm with integrated center disk and diaphragm. Replacement is extremely simple, and it has excellent running costs. | Resin Center Rod By using resin as the center rod material, non-metal is achieved. |

|

|

■ Employs Fiber-optic Stroke Sensor Control.

Employs a fiber-optic stroke sensor control model that can be used even in explosion-proof areas.

◆ Sensor Control “Fiber-Optic Stroke Sensor”

| Non-metal, Explosion-proof Model By including a fiber-optic stroke sensor, the pump can be used in explosion-proof areas. |

|

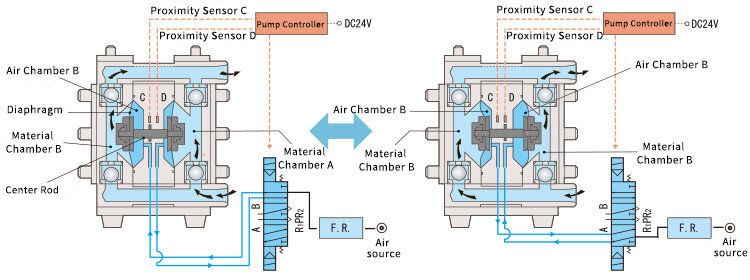

| Sensor Control = Stable Reciprocating Motion A proximity sensor detects the stroke end of the diaphragm, and the pump controller receiving the sensor signal controls the switching of the center exhaust type 3-position 5-port solenoid valve. |

| Optional Counter Connection Enables Stroke Management By counting the number of times the center rod has moved, it is possible to determine when parts need to be replaced. |

|

Specifications

| Valve Shape and Model Number | |||||

| Ball Valve | DP-10FsE | DP-10FsE | DP-20FsE | DP-20FsE | |

| Body Material | |||||

| Center Body | Polypropylene (PPG) | ||||

| Pump Body | PTFE | ||||

| Wetted Parts Material | |||||

| Diaphragm PTFE | PTFE | ||||

| Valve PTFE | |||||

| Valve Seat PTFE | |||||

| Valve Stopper PTFE | |||||

| Center Disk PFA | Integrated with diaphragm | ||||

| Specifications | |||||

| Nominal Diameter | 3/8″ (10 mm) | 3/4″ (20 mm) | |||

| Material Connection | Suction Port | Rc 3/8 (F) | JIS flange 10K 10A equivalent | Rc 3/4 (F) | JIS flange 10K 20A equivalent |

| Discharge Port | |||||

| Air Connection | Supply Port | Rc 1/4 x 2 (Shared supply and exhaust port x 2) *1 | |||

| Exhaust Port | |||||

| Air Supply Pressure | 0.2~0.5 MPa *2 | ||||

| Maximum Discharge Pressure | 0.5 MPa | ||||

| Water Discharge/Cycle | 60 mL *3 | 180 mL *3 | |||

| Maximum Flow Rate | 20 L/min | 45 L/min | |||

| Maximum Air Consumption | 350 L/min (ANR) | 450 L/min (ANR) | |||

| Maximum Size Solid | Maximum 1 mm | Maximum 2 mm | |||

| Viscosity Limit | Maximum 1 Pa·s | Maximum 2 Pa·s | |||

| Temp Range | Ambient | 0~70 °C | |||

| Liquid Temperature | 0~80 °C | ||||

| Noise Level | 80 dB | 82 dB | |||

| Net Weight | 11.3 kg | 18.6 kg | |||

*1 The pipe length from the air supply valve (solenoid valve, etc.) to the pump shall be 1.5 m or less. If piping from the exhaust port of the air supply valve to another location, the pipe length to the end of the exhaust port shall be 5 m or less.

*2 The compressed air quality shall satisfy quality classes both 2 and 3 specified in “JIS B8392-1:2000 Compressed air for general use.”

(Maximum particle diameter: 1 μm, Maximum open air pressure: -20°C, Maximum oil concentration: 0.1 mg/m3)

The maximum supply air pressure of a type with a resin-made pump body depends on the liquid temperature.

*3 The water discharge is provided as a rough approximation only. The discharge will differ depending on factors such as the liquid to be transferred and the piping conditions.